MIM Parts have been widely used in the automotive manufacturing industry; Due to its high production efficiency, it can meet the requirements of the automotive industry for supply speed; In addition, many wearing parts need to be replaced frequently, and the production cost of MIM can adapt to this demand; The superior performance of its own structure and good heat treatment performance ensure its strength and toughness, and can also meet the requirements of some oil content and high vibration resistance and buffering. At present, common applications are: ignition control lock parts, turbocharger rotors, valve guide rail parts, automotive brake device parts, automotive sun protection shed parts, clutch inner ring, scotch fork sleeve, distributor sleeve, automotive conduit, etc.The external parts of some cars, if made directly of plastic and metal materials, are easy to age in the outdoor environment, while MIM parts have good temperature and temperature characteristics and can be used outdoors; At the same time, the fragility and rust of outdoor parts, the use of MIM production cost is low, regular replacement is a good choice; Some automobile parts are huge in number, and other processes cannot meet the requirements of efficiency, and MIM can achieve the needs well in terms of production capacity; A large number of interior parts in the car interior, can use MIM to produce the appearance using different processing processes, to achieve good decorative performance and the need for replacement at any time;

MIM Parts have been widely used in the automotive manufacturing industry; Due to its high production efficiency, it can meet the requirements of the automotive industry for supply speed; In addition, many wearing parts need to be replaced frequently, and the production cost of MIM can adapt to this demand; The superior performance of its own structure and good heat treatment performance ensure its strength and toughness, and can also meet the requirements of some oil content and high vibration resistance and buffering. At present, common applications are: ignition control lock parts, turbocharger rotors, valve guide rail parts, automotive brake device parts, automotive sun protection shed parts, clutch inner ring, scotch fork sleeve, distributor sleeve, automotive conduit, etc.The external parts of some cars, if made directly of plastic and metal materials, are easy to age in the outdoor environment, while MIM parts have good temperature and temperature characteristics and can be used outdoors; At the same time, the fragility and rust of outdoor parts, the use of MIM production cost is low, regular replacement is a good choice; Some automobile parts are huge in number, and other processes cannot meet the requirements of efficiency, and MIM can achieve the needs well in terms of production capacity; A large number of interior parts in the car interior, can use MIM to produce the appearance using different processing processes, to achieve good decorative performance and the need for replacement at any time;

2. If Auto parts are prone to aging in an outdoor environment, MIM parts have good temperature and temperature characteristics and can be used outdoors. Connecting rods, pendulum connecting rods, bearings, wipers, etc.

2. If Auto parts are prone to aging in an outdoor environment, MIM parts have good temperature and temperature characteristics and can be used outdoors. Connecting rods, pendulum connecting rods, bearings, wipers, etc.

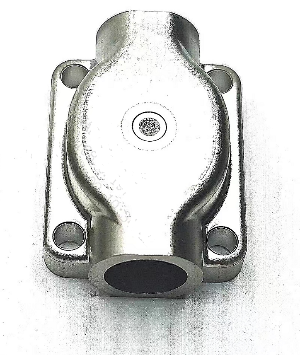

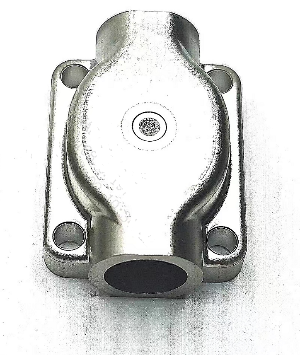

3. Bushings are cylindrical mechanical parts mounted on a rotating shaft and are an important part of plain bearings. The material must not only have the hardness of the base metal, but also require unique cutting forming, MIM parts are injection molded at one time, and no additional cutting is required to meet the requirements use.

3. Bushings are cylindrical mechanical parts mounted on a rotating shaft and are an important part of plain bearings. The material must not only have the hardness of the base metal, but also require unique cutting forming, MIM parts are injection molded at one time, and no additional cutting is required to meet the requirements use.